Operating a strapping machine requires certain safety precautions to ensure the well-being of operators and prevent accidents.

Familiarize yourself with the operation and safety guidelines provided by the manufacturer in the instruction manual. Understand the specific safety features and recommended operating procedures for the particular strapping machine model you are using.Only trained and authorized personnel should operate the strapping machine. Ensure that operators receive comprehensive training on the safe operation of the specific machine model, including knowledge of emergency shutdown procedures and troubleshooting techniques.

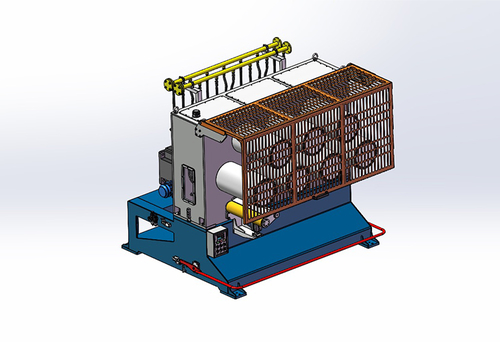

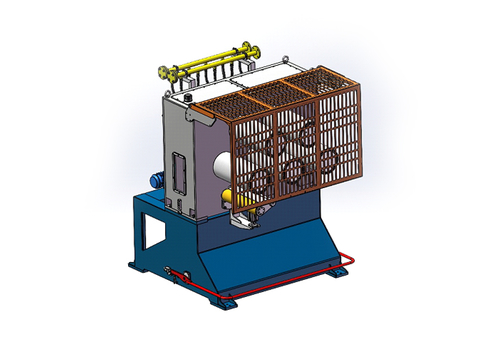

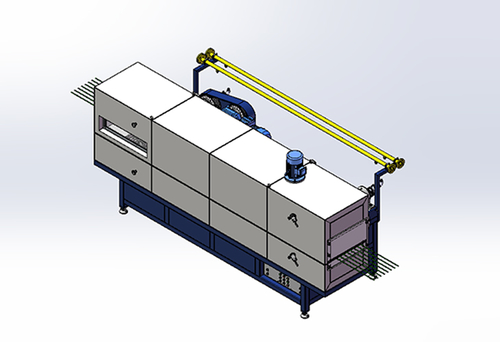

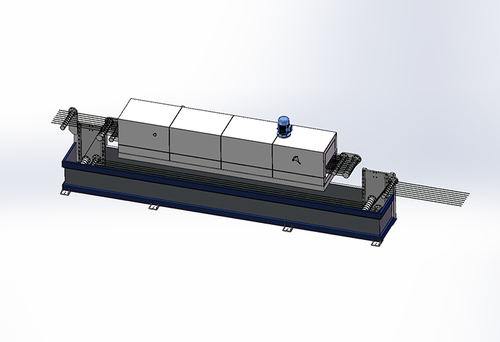

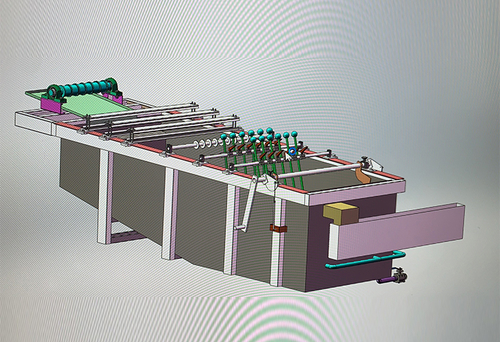

Before operating the

strapping machine, conduct a visual inspection to ensure that all components, such as the strapping material feed system, tensioning unit, and sealing mechanism, are in proper working condition. Look for any signs of damage or wear that could compromise safety or performance.

Always wear appropriate PPE, such as safety glasses, gloves, and steel-toed shoes, to protect yourself from potential hazards. Some machines may require additional safety gear, so refer to the manufacturer's guidelines for specific requirements.

If the strapping machine is electrically powered, take precautions to prevent electrical hazards. Ensure that the machine is properly grounded, and do not operate it in wet or damp environments. Avoid exposing the machine or its power cords to water or other liquids.

Emergency Stop Button: Familiarize yourself with the location and operation of the emergency stop button or switch on the machine. In case of an emergency or hazardous situation, quickly press or activate the emergency stop to halt the machine's operation.

Material Handling: Handle strapping materials with care to prevent injuries. Sharp edges on strapping materials or the machine itself can cause cuts or lacerations. Use proper lifting techniques when loading strapping materials onto the machine and avoid overloading.

Clear Work Area: Keep the work area around the strapping machine clean and free of clutter. Remove any obstacles or trip hazards to ensure smooth operation and prevent accidents. Maintain a safe distance from moving parts while the machine is in operation.

Lockout/Tagout Procedures: When performing maintenance or repair tasks, follow lockout/tagout procedures to safely isolate the machine from its power source. This prevents accidental startup or movement of the machine while maintenance work is being conducted.

Reporting Issues: Promptly report any malfunctions, abnormalities, or safety concerns related to the strapping machine to the appropriate personnel or supervisor. Do not operate a machine that is not functioning properly or if there is a safety risk.