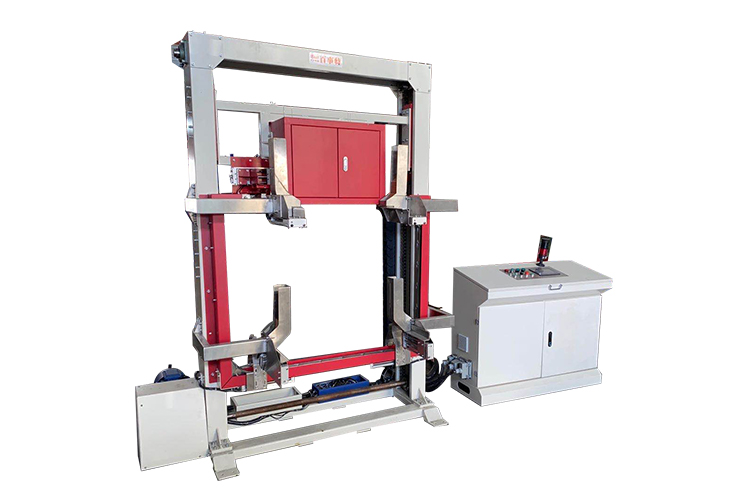

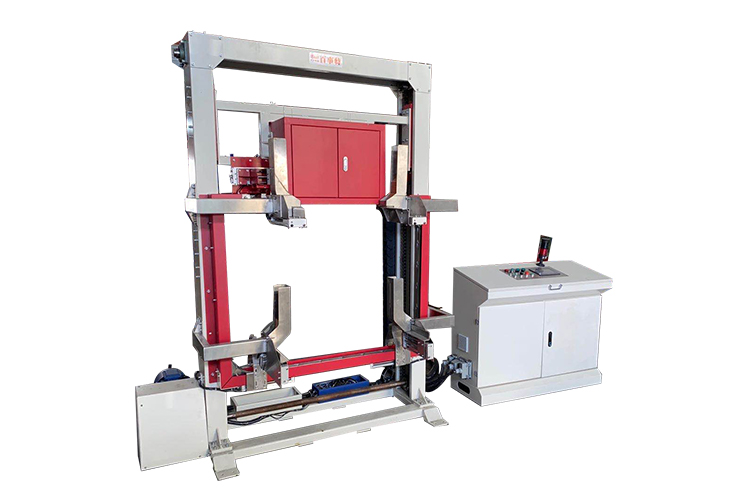

Draw stand -heavy-duty structure in welded steel -cylinder diam. with 270, 318, 415mm -radial tittup of the rolls +/- 0.2mm -speed accuracy +/- 0....

Draw stand -heavy-duty structure in welded steel -cylinder diam. with 270, 318, 415mm -radial tittup of the rolls +/- 0.2mm -speed accuracy +/- 0....

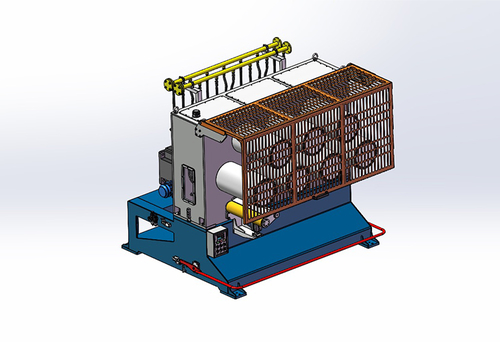

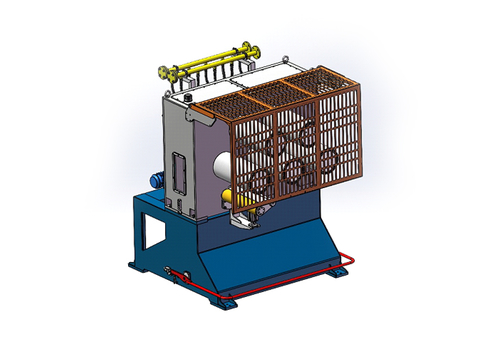

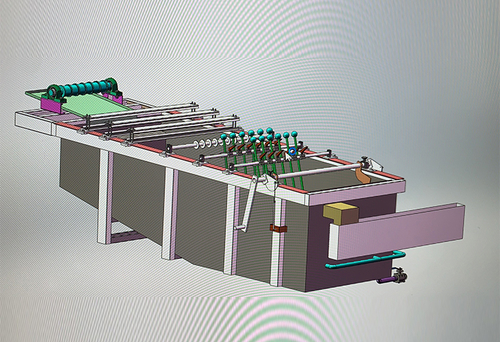

-with motorized and thermo-regulated stretching roller, with 3 passages of material, working width 400mm, 500mm, 600mm, useful length 4000mm. -tempe...

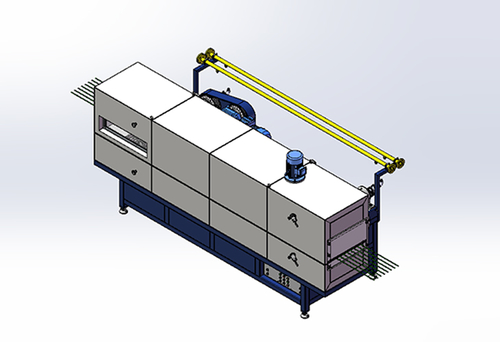

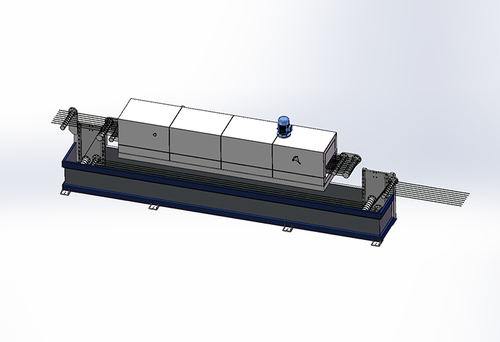

Relaxing oven -working width 400, 500, 600mm, 5 passages of material useful length 4 meters -air flow speed adjustable by inverter - temperature acc...

Cooling water tank The melt from die head is cooled down in water until solidification. -motor driven vertical adjusting of the tank with vertical ad...

Manual bobbin changeover -with one or two winding mandrels - winding of PP or PET strap - central input terminal with recipe manag...

Get A Free Quote For Project