Using a

strapping machine in packaging operations offers several benefits. Here are some key advantages:

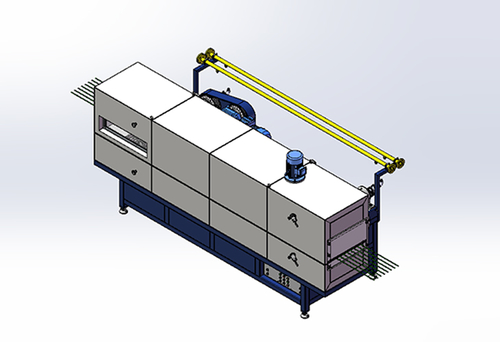

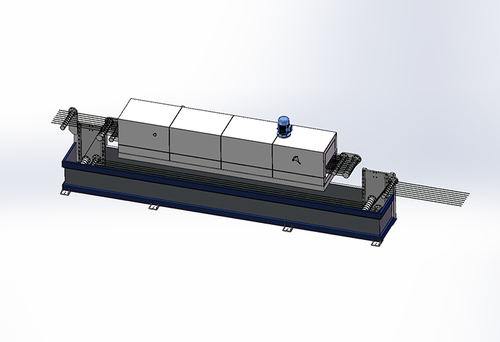

Efficiency and Time-saving: Strapping machines automate the strapping process, allowing for faster and more efficient packaging operations. A faster strapping machine allows for higher throughput and increased productivity. With quicker cycle times, more packages can be strapped within a given timeframe. This is especially beneficial for businesses dealing with large volumes of packages or tight production schedules. The speed of a strapping machine directly affects the time required to complete the packaging process. Faster machines can strap packages more quickly, reducing the overall time spent on each package. This time efficiency enables businesses to meet deadlines, fulfill customer orders promptly, and optimize their operational efficiency.

Consistency and Uniformity: Strapping machines provide consistent tension and sealing, resulting in uniform and secure straps across all packages. This helps maintain the integrity of the packaged goods and ensures they are properly secured for transportation or storage.

Cost-effective: While the upfront investment for a strapping machine may be higher compared to manual strapping methods, it offers long-term cost savings. Automated strapping reduces the need for additional labor, reduces material waste due to consistent tensioning, and minimizes the risk of product damage during transit. These factors contribute to cost reduction and improved profitability in the long run.Speedy strapping machines can contribute to cost savings by reducing labor costs. Since more packages can be strapped in a shorter period, fewer operators may be needed for the packaging process. This leads to reduced labor expenses, allowing businesses to allocate resources more efficiently.

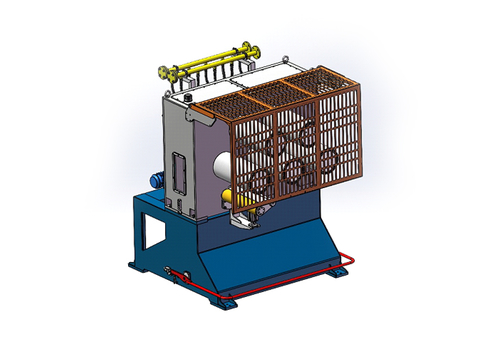

Increased Safety: Strapping machines are designed with safety features to protect operators from potential injuries. They often have mechanisms to prevent accidental activation, minimize operator strain, and ensure safe operation during the strapping process. This reduces the risk of workplace accidents and promotes a safer working environment.

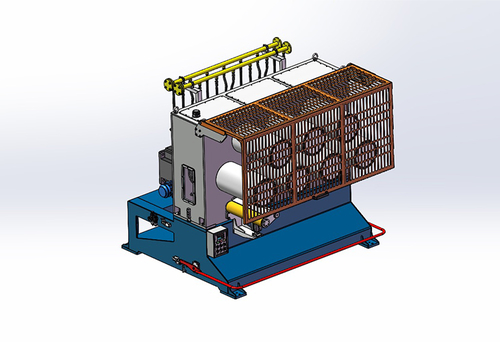

Versatility: Strapping machines can handle various types of strapping materials, such as plastic, steel, or polyester, allowing businesses to choose the most suitable option for their specific packaging requirements. Additionally, they can accommodate different package sizes, shapes, and weights, making them versatile for a wide range of applications.

Enhanced Packaging Security: Strapping machines provide strong and secure straps that hold packages tightly together, minimizing the chances of tampering, theft, or damage during transit. This is particularly beneficial for shipping valuable or fragile items that require extra protection.

Streamlined Integration: Strapping machines can be seamlessly integrated into existing packaging lines or systems, allowing for smooth operations without major disruptions. They can be synchronized with other packaging equipment, such as conveyors or automated palletizers, further optimizing the packaging process.In industries that involve time-sensitive shipping or distribution, faster strapping machines can play a crucial role in meeting delivery deadlines. Packages can be strapped quickly and efficiently, enabling prompt loading onto trucks or pallets. This ensures that packages are ready for shipment without causing delays in the logistics chain.